PROJECT OVERVIEW

In response to the need for compact, high-performance thermal management systems, this project focused on the design and simulation of CHIMES (Compact High-Performance Microchannel Evaporator System)—a capillary-driven cooling solution for ultra-dense electronics. The objective was twofold:

- Numerically simulate phase-change dynamics and capillary behavior under various initial states.

- Redesign and validate an experimental prototype incorporating PDMS sealing for reliability and manufacturability.

METHODS & APPROACH

SIMULATION PHASE

- Developed a detailed 3D CFD model using polyhedral meshing (~487k elements) with 1 µm resolution.

- Implemented boundary conditions for capillary-driven flow (1 atm pressure inlet/outlet, symmetry).

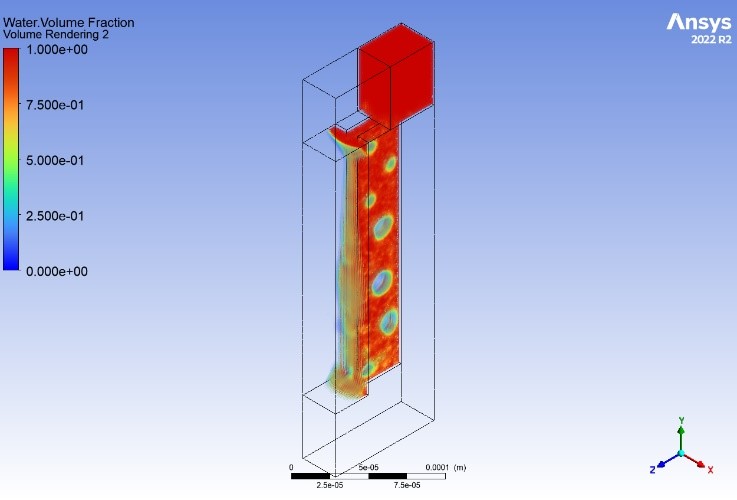

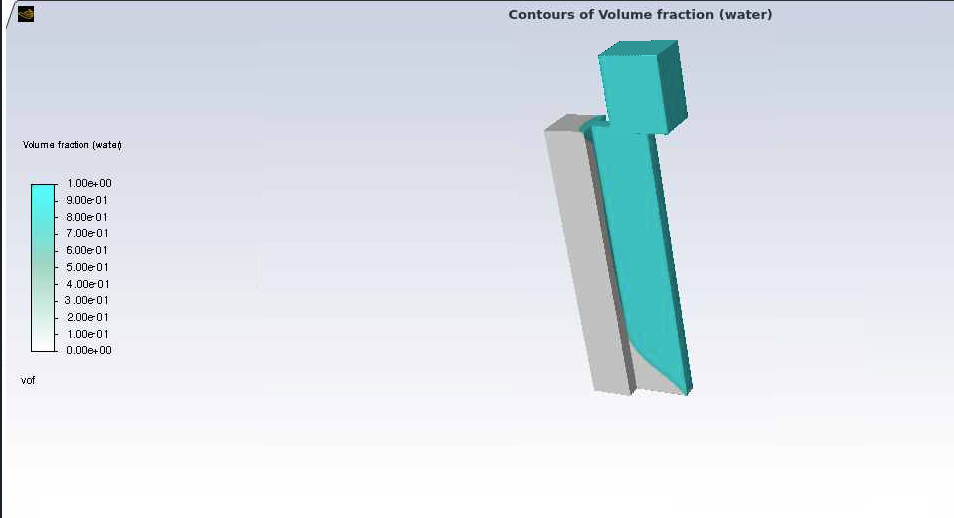

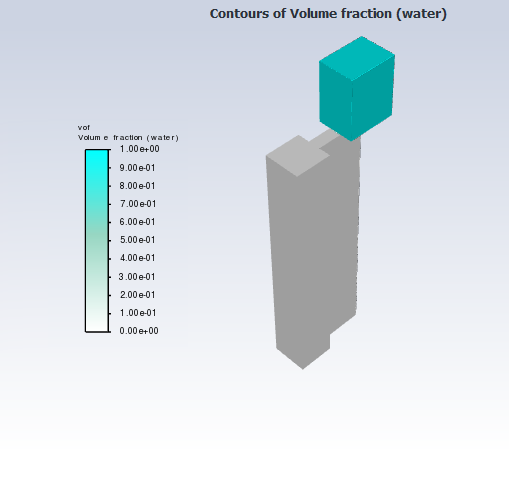

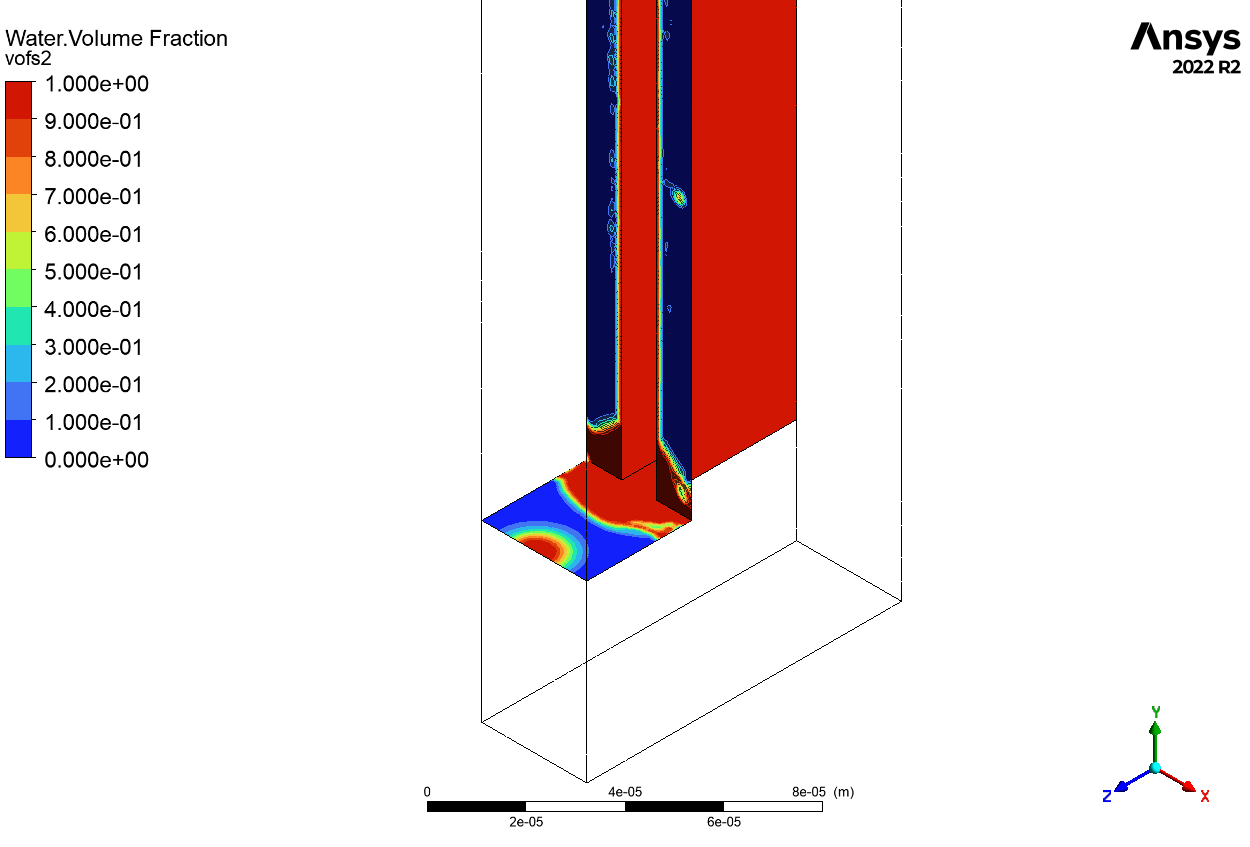

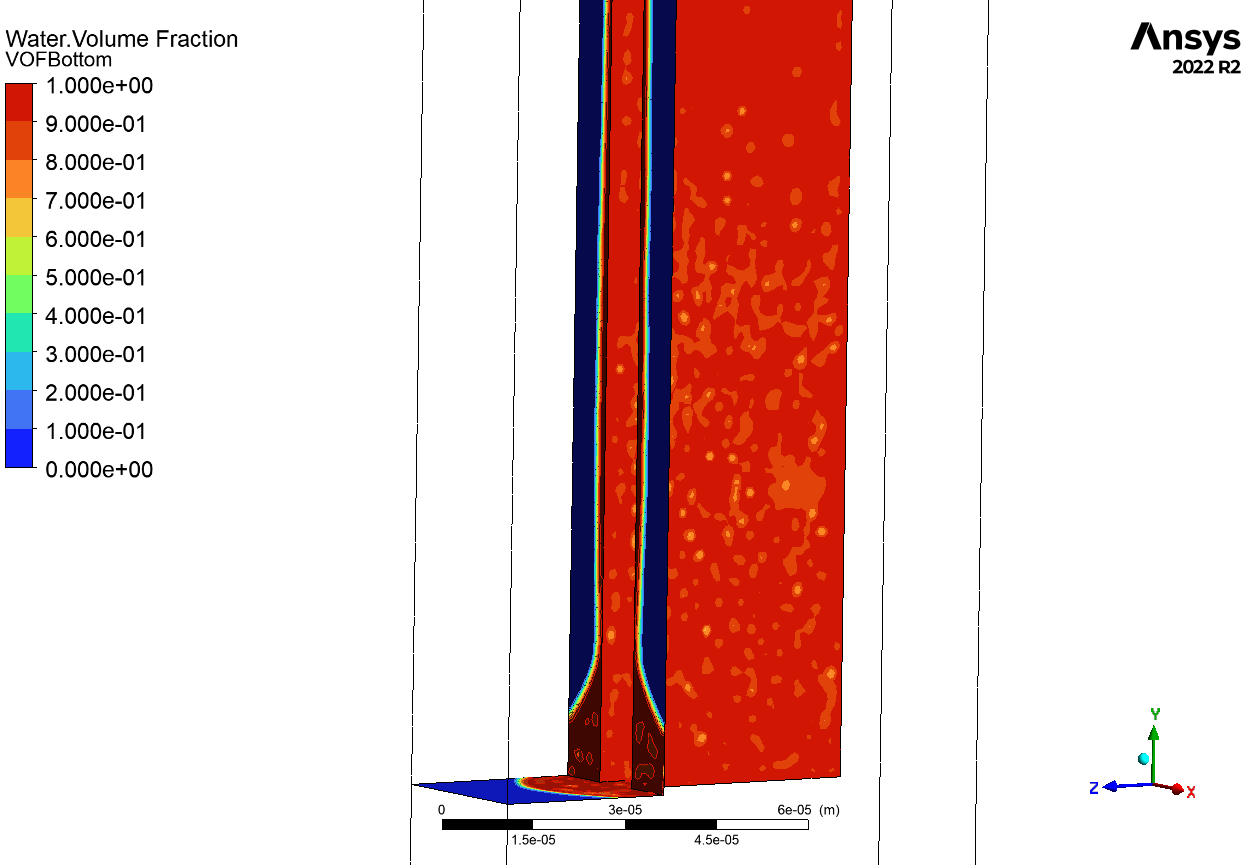

- Used a VOF (Volume of Fluid) multiphase model to simulate interface evolution from:

- Flooded channel

- Meniscus-formed channel

- Dried-out channel

- Introduced an energy jump model at the liquid-vapor interface to simulate evaporation as a thermal discontinuity, enabling robust yet efficient handling of phase change.

- Compared wall temperature results: Flooded (~380 K) vs. Meniscus (~375 K), validating HTC behavior.

EXPERIMENTAL PHASE:

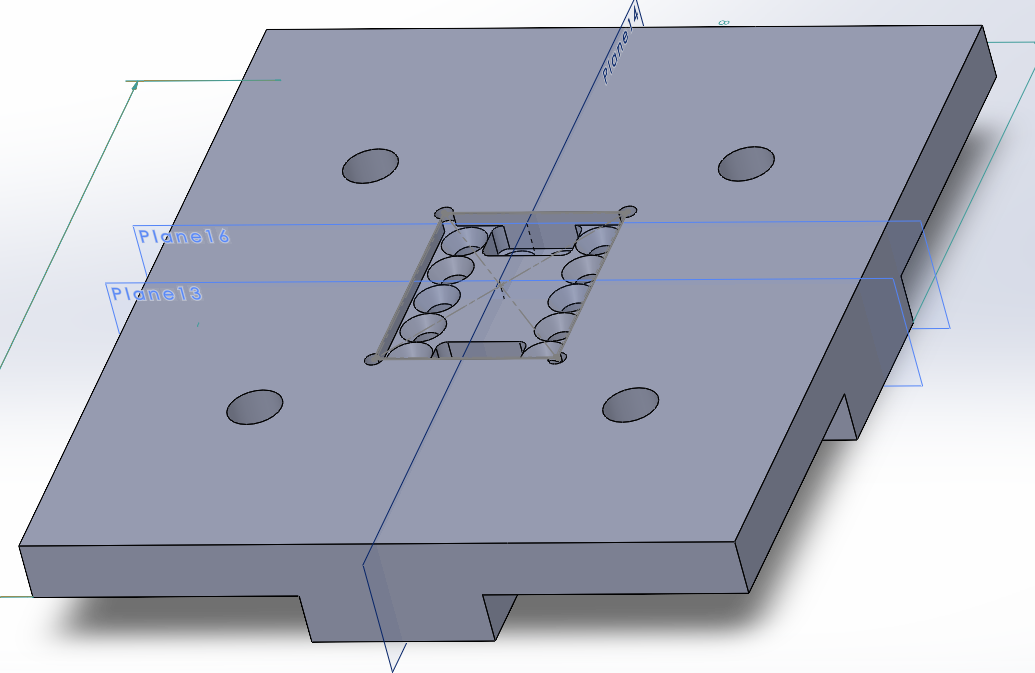

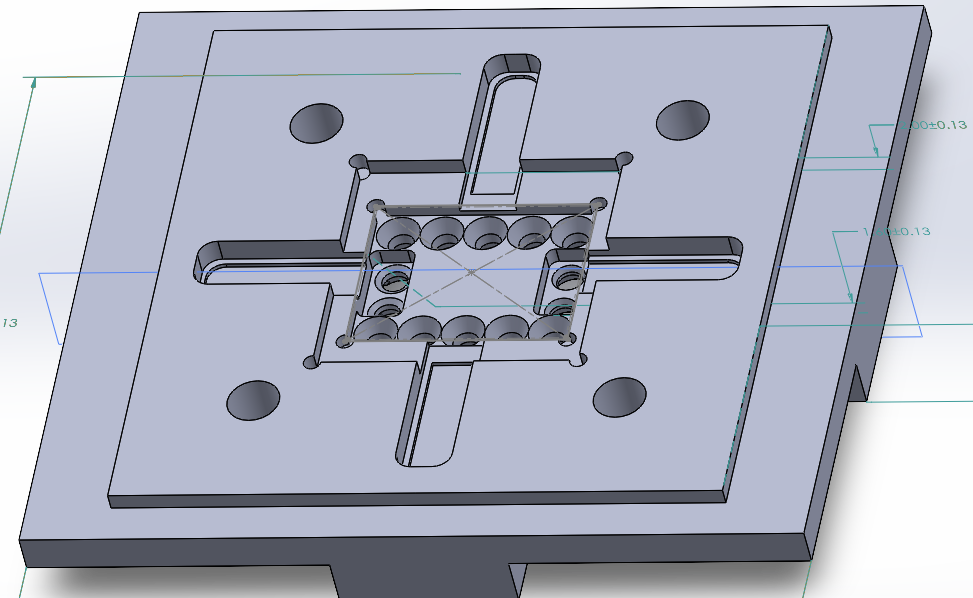

- Addressed leakage and support issues by redesigning the bottom plate to integrate PDMS sealing.

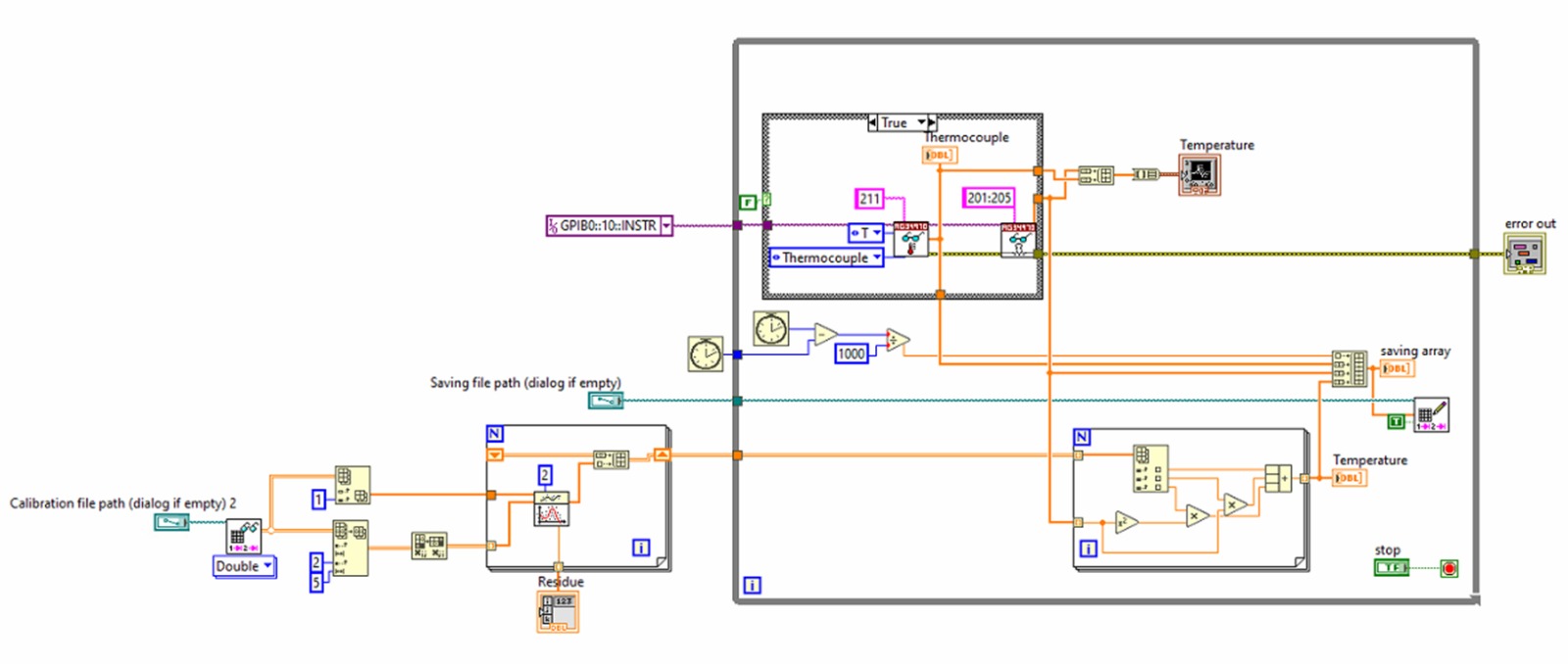

- Built LabVIEW-controlled setups with thermocouples to monitor real-time TIM interface temperatures under dynamic conditions. Integrated DAQ hardware with calibrated CJC to log temperature differentials, identify thermal failure paths, and validate cooling strategies.

Change From

Change To

RESULT AND IMPACTS

- Simulation Findings::

- The meniscus configuration resulted in more favorable boiling conditions and better heat dissipation.

- Confirmed that energy jump modeling effectively captures interface evaporation phenomena with minimal computational complexity.

- Experimental Advancements:

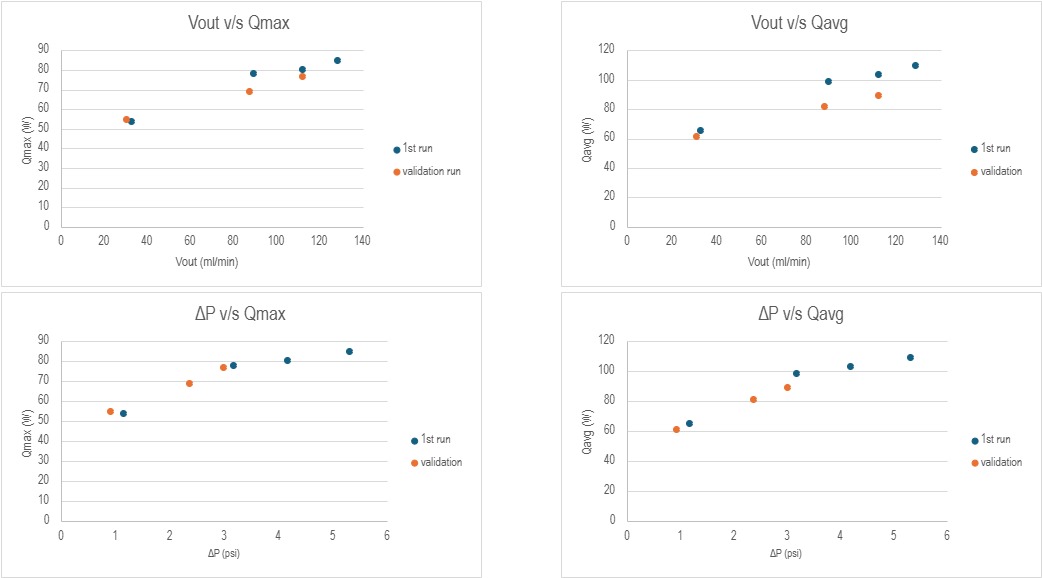

- Experimentally measured and calculated maximum and average dissipated powers at each studied flow rate, extrapolated from experimental thermal resistance for a set surface temperature of 105 °C

TOOLS & TECHNOLOGIES

- Software: ANSYS Fluent, CAD (Creo), MATLAB

- Simulation Methods: VOF multiphase modeling, energy jump condition, polyhedral meshing

- Materials: Silicon, PDMS, glass, PC, TIM

- Measurement Goals (Future): Thermal resistance, boiling onset, channel flooding

FUTURE SCOPE

- Simulate pumping-driven flow and validate flooding vs. dry-out at higher heat fluxes.

- Fabricate and test the redesigned CHIMES prototype using the new PDMS-enabled structure.

- Integrate heat source instrumentation and conduct thermal performance benchmarking under transient loads.