PROJECT OVERVIEW

The Problem

Fused Deposition Modeling (FDM) 3D printers are prone to operational issues like nozzle blockages and material run-out, which often go undetected during printing, leading to failed builds and wasted resources.

The Goal

To develop a machine learning-based system capable of classifying real-time 3D printer operating conditions (normal, semi-blocked, blocked, run-out) using acoustic emission (AE) sensor data.

The Context

The project explores non-invasive monitoring via AE sensing and data-driven classification to improve reliability and autonomy in additive manufacturing processes.

METHODS & APPROACH

Your Contributions

Preprocessed AE signal data, applied log transformations to skewed features, trained and tuned the Random Forest model, and performed model benchmarking and analysis.

Your Methodology

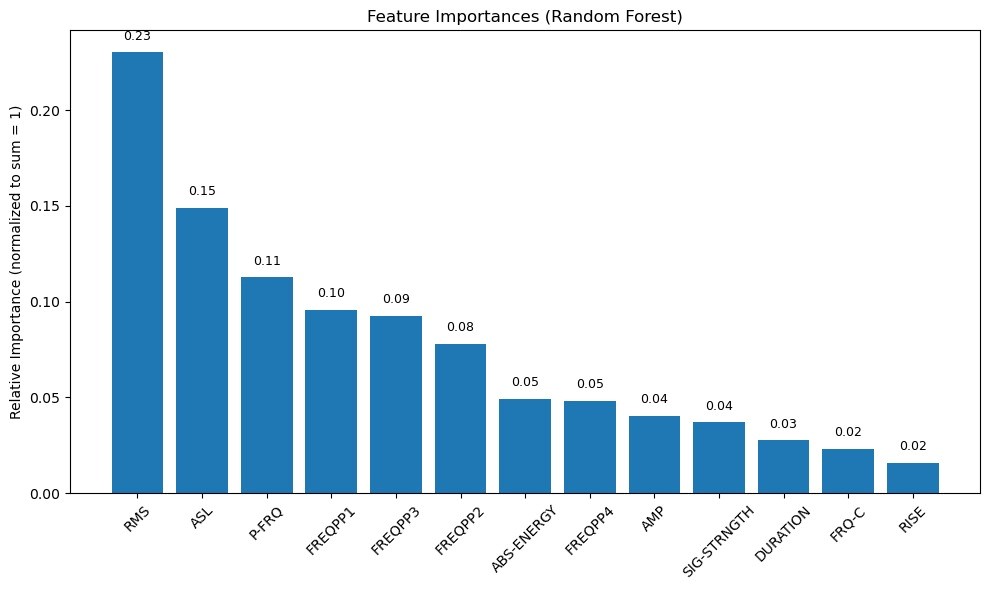

- Extracted 13 AE features from pre-segmented signal windows (e.g., RMS, ABS-ENERGY, ASL, Peak Frequency).

- Applied log1p transformation to reduce skew in energy-based features.

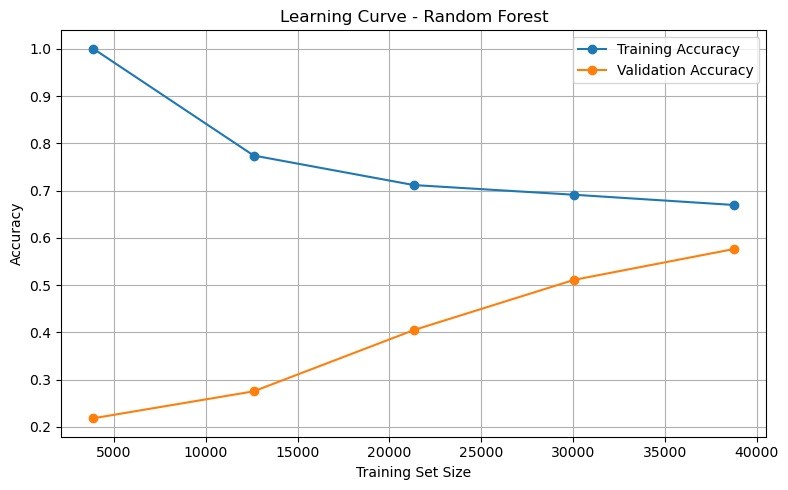

- Used Random Forest (200 trees, max depth = 10) for classification.

- Compared results to an SVM with RBF kernel, replicating a baseline from prior research (Wu et al., 2016).

- Evaluated using confusion matrices, feature importance, and learning curves.

Your Unique Angle

Leveraged feature importance and custom preprocessing to enhance model interpretability and optimize performance for real-world signal variability.

OUTCOME & IMPACT

Results

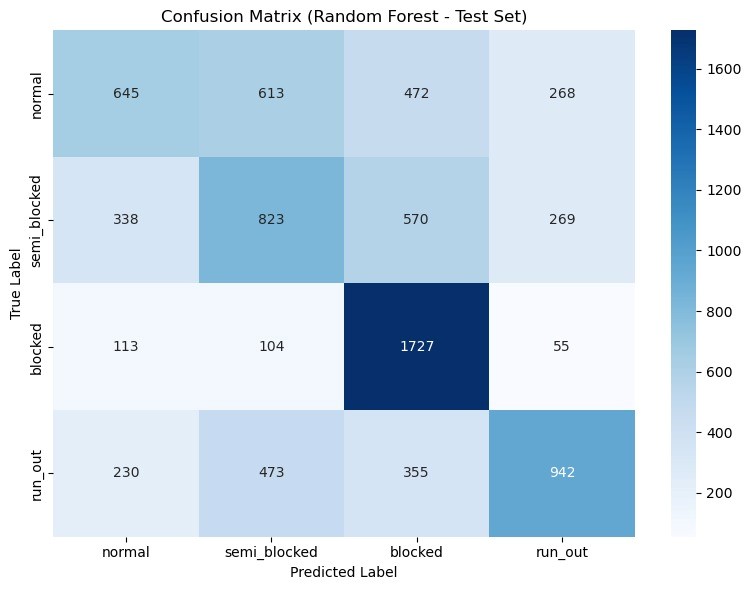

Overall Accuracy (Random Forest): 51.73%

Blocked Condition Accuracy: 86.39%

SVM Baseline Accuracy: 48.38%

Top Features: RMS, ASL, and ABS-ENERGY (log-transformed)

Key Insights

The model was highly effective at identifying severe faults (blocked, run-out).

Difficulty in distinguishing normal vs. semi-blocked conditions points to the need for more granular features or time-series models.

Real World Impact

This method provides a cost-effective, scalable pathway to real-time fault detection in FDM systems—critical for ensuring print quality in automated manufacturing environments.

LESSONS LEARNED & FUTURE PLANS

What You Learned

Gained hands-on experience in signal-based feature engineering, supervised classification, and model evaluation using real-world noisy datasets.

Future Applications

Plans include deploying time-series models like 1D CNNs or LSTMs to capture temporal dependencies and deploying models on edge devices for real-time feedback.

Next Steps

- Expand the AE dataset with different materials and printing parameters.

- Test integration with live 3D printing systems.

- Improve class separation through confidence filtering and dimensionality reduction (e.g., PCA, t-SNE).