PROJECT OVERVIEW

With the rise of high-performance, miniaturized electronics, ultra-fine pitch flip-chip assemblies using glass core substrates are emerging as next-generation packaging solutions. However, these structures face major thermomechanical reliability challenges—primarily fatigue failure of solder joints under cyclic thermal loading.

To address this, we developed a detailed finite element modeling (FEM) framework focused on Level 1 assembly (die-on-glass) using a 50 μm solder bump pitch. Our simulation methodology integrates material-level viscoplasticity, parametric design variation, and fatigue life prediction to identify failure modes and propose design mitigation strategies.

FAILURE MODE & RISK CONTEXT (FMEA-Informed Framing)

Failure Mode

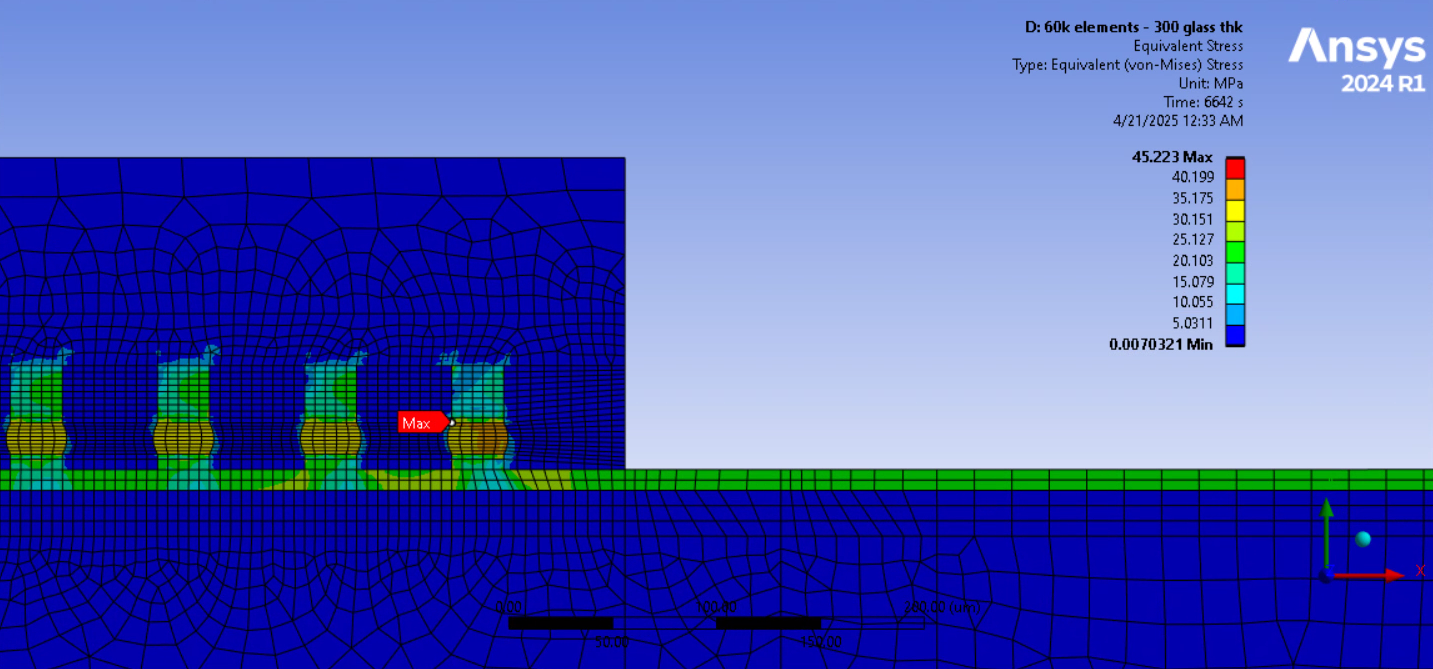

Low-cycle fatigue at solder joints due to plastic strain accumulation

Root Cause

CTE mismatch between silicon, glass, underfill, and solder materials

Effect

Cracking at die corners → electrical disconnect → long-term failure

Risk Level (RPN)

135 (High) = Severity (9) × Occurrence (5) × Detection (3)

Detection & Mitigation

Detection: FEM simulation (ANSYS), Anand viscoplastic modeling, validated via corrected Suhir model

Mitigation: Parametric FEM analysis on glass thickness and underfill coverage

TECHNICAL APPROACH

FATIGUE ANALYSIS

- Accumulated plastic strain extracted from stabilized cycles

- Fatigue life estimated using: Kanchanomai model and Andersson model

- Conservative design chosen by selecting lower of the two predictions

MATERIAL BEHAVIOR

- SnAg solder modeled with Anand viscoplasticity

- Copper: bilinear isotropic hardening

- Glass, silicon, ABF-Cu, underfill: temperature-dependent elastic models

- Thermal cycling from –55°C to 125°C applied over 11 cycles (JEDEC JESD22-A104 Condition B)

GEOMETRY & MODELING

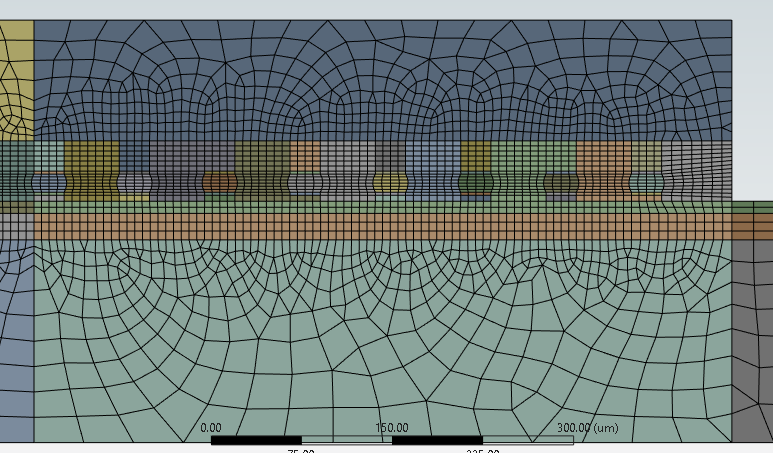

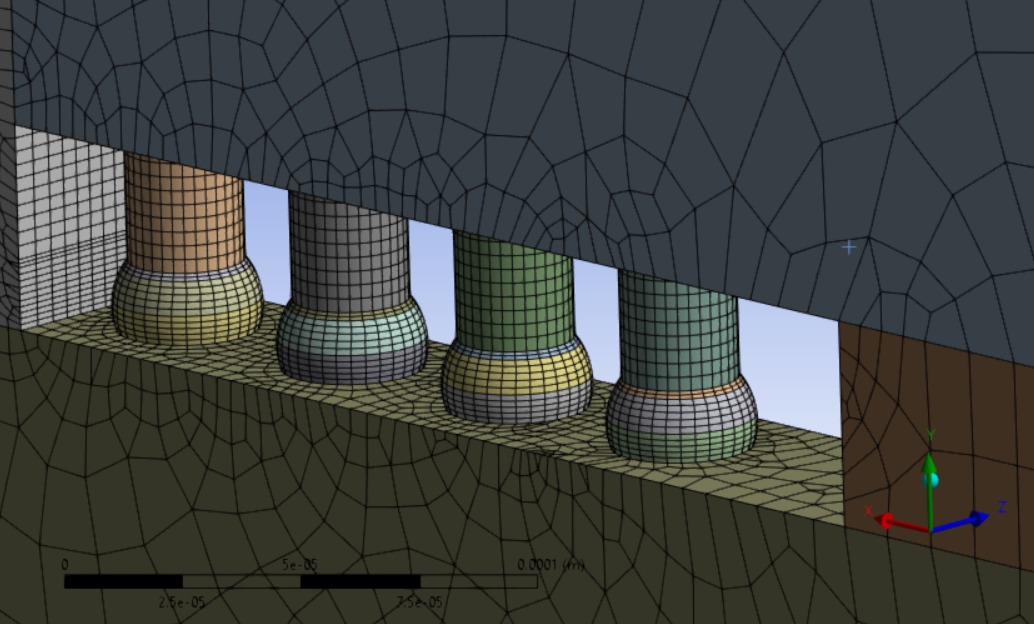

2D plane strain model of diagonal flip-chip cross-section

- 2D plane strain model of diagonal flip-chip cross-section

- Shared topology meshing for accurate stress continuity

- Fine mesh at solder joints to capture stress gradients

- PLANE183 elements used for nonlinear plasticity and viscoplastic behavior

PARAMETRIC DESIGN OPTIMIZATION

VARIABLES STUDIED

- Glass thickness: 200 µm, 300 µm, 400 µm

- Underfill coverage: None, Half Fillet, Full Fillet

FINDINGS

- Stress trend: Non-linear; peaks at 300 µm then slightly decreases

- Deformation trend: Monotonically decreases with thicker glass

- Fatigue life: Best case at 400 µm glass + half underfill (Nf ≈ 2,494 cycles)

Optimization Results

| Configuration | Δε (%) | Cycles to failure (Kanchanomai) | Cycles to failure (Andersson) |

|---|---|---|---|

| 200 µm, no underfill | 1.95E-2 | 1,908 | 2,002 |

| 400 µm, half underfill | 1.67E-2 | 2,249 | 2,494 |

| 400 µm, full underfill | 1.73E-2 | 2,173 | 2,381 |

Non-linear stress trend with varying glass thickness

IMPACT

This study offers a validated simulation-based strategy to guide the design of reliable, high-density flip-chip assemblies for next-gen electronics. It pinpoints material and structural interactions that contribute to premature failure and proposes physically grounded optimizations to extend device lifespan.

From a systems engineering perspective, the work also provides a risk-reduction framework that integrates failure identification, sensitivity analysis, and simulation-validated design tradeoffs—critical for manufacturable, robust packaging solutions.

FUTURE WORK

- Extend to 2.5D and 3D models for improved Z-axis accuracy

- Investigate arc fillet profiles and organic substrates

- Study standoff height variations and multi-layer ABF effects

- Perform board-level FEM modeling (Level 2 assembly)

- Correlate results with experimental data from thermal cycle tests